INOTEC Electronics

Secure, robust, and reliable (Made in Germany with German components).

A leader for over 35 years in shielding interconnection systems from EMI/RFI (electromagnetic and radio frequency interference), Inotec continues to set standards through innovation, sustainability, and a sense of responsibility.

From the very beginning, Inotec has focused on applications with the highest standard in terms of disturbance-free signal and data transmission. Thanks to constant efforts in developing high-quality, advanced technology products, Inotec has positioned itself as the technological leader in the electromagnetic and radio frequency shielding (EMI/RFI) market for interconnected systems.

Secure, robust, and reliable (Made in Germany with German components).

A leader for over 35 years in shielding interconnection systems from EMI/RFI (electromagnetic and radio frequency interference), Inotec continues to set standards through innovation, sustainability, and a sense of responsibility.

From the very beginning, Inotec has focused on applications with the highest standard in terms of disturbance-free signal and data transmission. Thanks to constant efforts in developing high-quality, advanced technology products, Inotec has positioned itself as the technological leader in the electromagnetic and radio frequency shielding (EMI/RFI) market for interconnected systems.

Products offered by INOTEC Electronics:

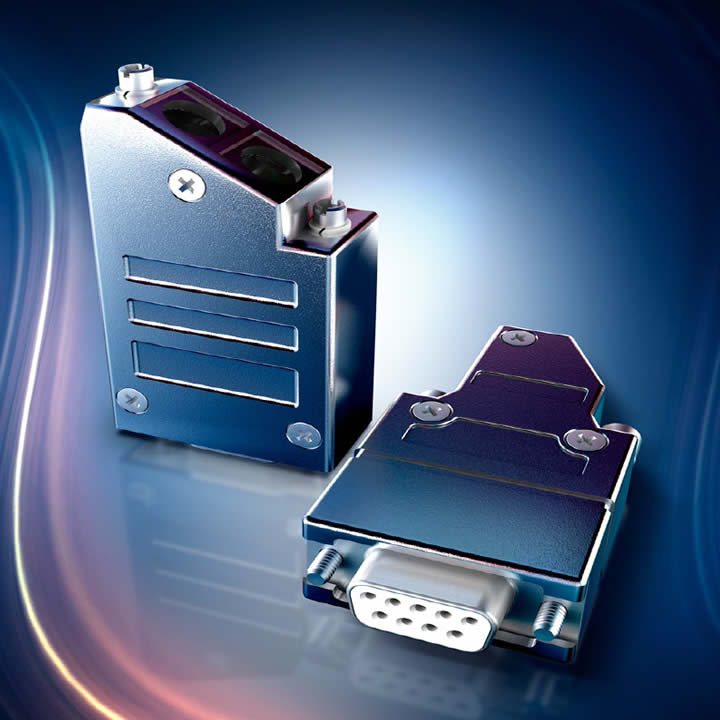

SUB-D Connectors

Fully metallic housings with various locking systems (sliding, pressure, and several screw types), a wide range of housing geometries, designs for specific applications such as MSB and MSBS bus connectors or DGA "piggy-back" adapters, and sophisticated solutions like the Sub-D coding system. Inotec Electronics currently offers the most extensive range of high-end metallic Sub-D connectors.

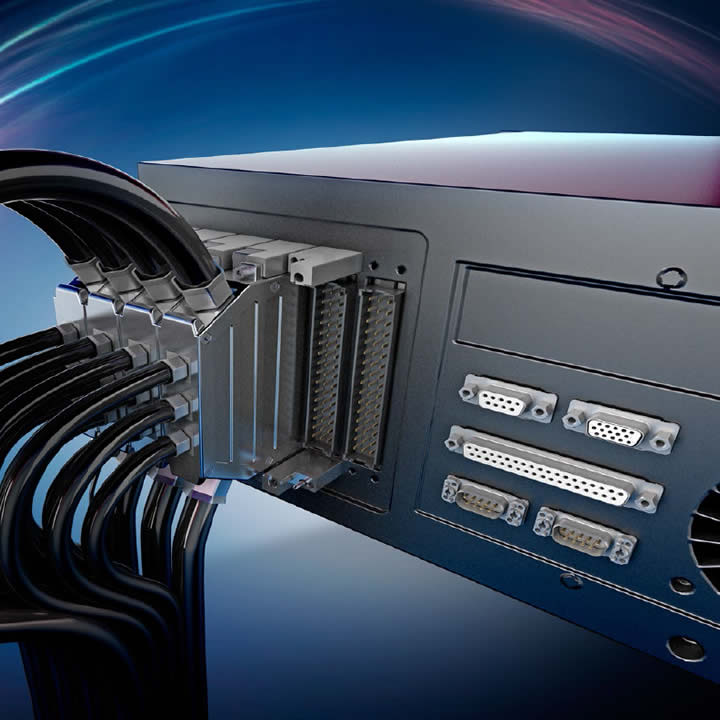

IEC 60603-02 Connectors

Robust housing system for 19” racks that comply with electromagnetic compatibility (EMC) standards.

Whether involving telecommunications equipment, industrial process control, or network adjustments, the interfaces for 19” racks IEC 60603-2 (DIN 41612) remain essential for multiple electronic systems.

Focused on EMC, robustness, and ease of assembly, Inotec has developed two complete housing systems, including the necessary connection elements to cover all common assembly situations: While the MSF-1/-3 is the classic solution for direct connection to the printed circuit board, the MSF-91/-92 allows for a separate installation of the interface between the final unit (including the printed circuit board) and the cable.

Due to its fully metallic components, the MSF-91/92 system offers a robust and reliable connection with a low-resistance ground contact between the connector housing and the 19” front panel.

For optimal HF protection, high tensile strength, and efficient processing, MSF housings should be used in combination with IMS crimping technology.

Circular Connectors

M12 MSR12/MRR12 Connection System

With the MSR12 / MRR12 series, Inotec Electronics has developed a circular connection system in accordance with DIN IEC 61076-2-101 standards. Thanks to its specially designed fully metallic housing, the system meets user demands for maximum EMI/RFI shielding in data transmission, combined with a robust and reliable connection. Another feature is its compact design that saves space and allows for easy assembly and installation.

The system is designed for an extended temperature range from -55°C to +150°C and still meets fire and smoke specifications for the railway industry.

High-end special contacts with gold plating ensure minimal transition resistance even after more than 500 connection and disconnection cycles.

Due to the precisely turned crimp contacts, not only are low contact resistances achieved, but optimal connection with the cable is also ensured. As an alternative to stamped M12 connectors, the MSR12/MRR12 series is aimed at applications requiring field assembly or individual wiring. Inotec’s original crimping system provides 360º contact with the cable shielding and ensures optimal tensile strength without exerting pressure on the cable core. The primary application area for the MSR12/MRR12 is the transmission of weak low-voltage signals or data in shielded cables. In particular, they are used for industrial Ethernet and fieldbus applications such as Profibus, Profinet, Ethernet/IP, Sercon, CAN Bus, and other protocols applied, for example, in data transmission within the railway industry.

These applications require a high level of shielding against interference, such as in control and monitoring networks or passenger information systems. Another crucial factor in these types of networks is mechanical robustness. Tensile and torsion resistance for signal or data transmission lines, when cables are bent or stretched, is as important as the vibration resistance of connections to the terminal unit.

While several conventional Ethernet connectors, such as the widely used RJ45, are not suitable for these mechanical load cases, the coded D M12 connectors represent the optimal standard solution. Inotec offers 4 A-coded interface shapes as options. Additional variants or designs can be developed according to specific customer needs.

M12 Connection System for Field Assembly

The Inotec M12 connection system has been specially designed for field assembly of connections with extreme requirements for robustness and electromagnetic shielding. The basic encapsulation design facilitates fault-free assembly. The high-precision turned crimp contacts with top-quality gold plating provide secure data transmission and low contact resistance even after more than 500 connection and disconnection cycles.

As the first circular connector to use Inotec's original crimping system, the system features unique qualities such as 360º contact with the shielding and high tensile strength.

M12 Connection System for Field Assembly

Inotec's exclusive crimping technology, with its unparalleled 360º contact with the shielding, can also be integrated into other standard circular connector systems. Especially in military applications, connectors must meet extreme requirements for EMC, robustness, and reliability. For this reason, Inotec offers special adapters to apply its crimping system to MIL-standard connectors. Due to their special design with a unique edge for heat shrink tubing, these adapters also enable IP67 sealing in the crimping area.

Designs for machine tools, equipment construction, and even engineering plants often require complex configurations in small quantities. For this reason, units are frequently connected by a direct cable rather than a plug-in cable. Especially in these cases, Inotec combines its crimping technology with integration into a single piece. Available in key sizes starting from M8, these components provide an extremely robust direct connection with an exceptional level of shielding and optionally IP67 sealing by adding heat shrink tubing.

The adapters are manufactured according to cable crimping specifications and are optimized for special applications.

Services offered by Connecta

Cable assembly service

Connecta Elementos y Sistemas, S.L. offers a precision coaxial cable assembly service that enables the creation of high-quality assemblies. Our assembly plant is equipped with precision equipment, allowing us to provide a fast and accurate service. We have the experience and flexibility necessary to meet the needs of any customer, regardless of the manufacturer or type of coaxial cable. Additionally, we offer a customization service for assemblies so you can obtain products that perfectly meet your requirements.

Also available upon request are cables with phase matching or individual measurement of return losses. Our customized cables offer performance and reliability. You can review the available options and request a quote from us. .